Are You Looking for Something to Outperform the Norm?

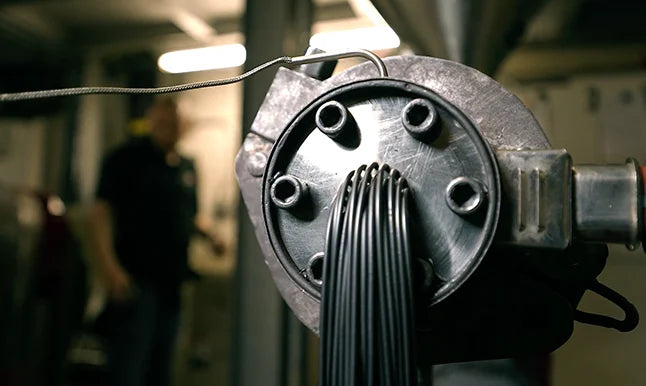

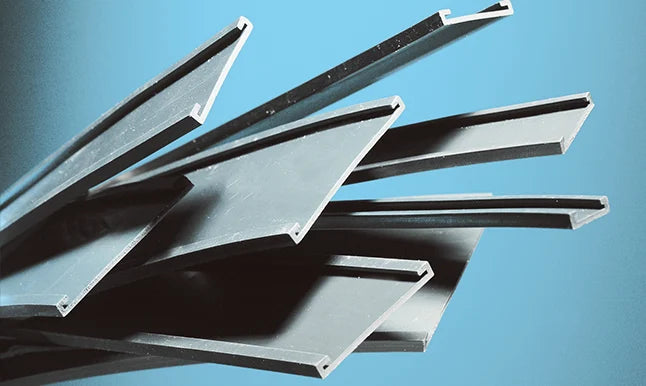

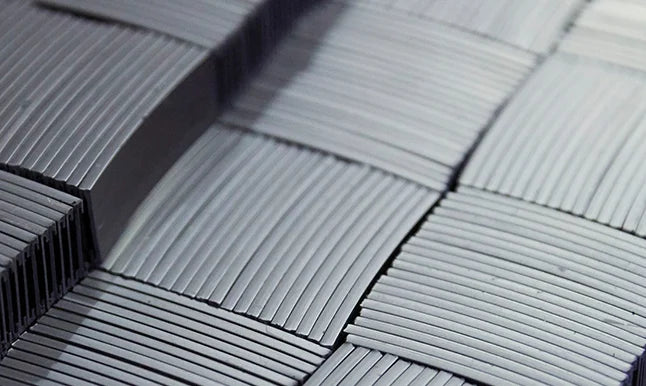

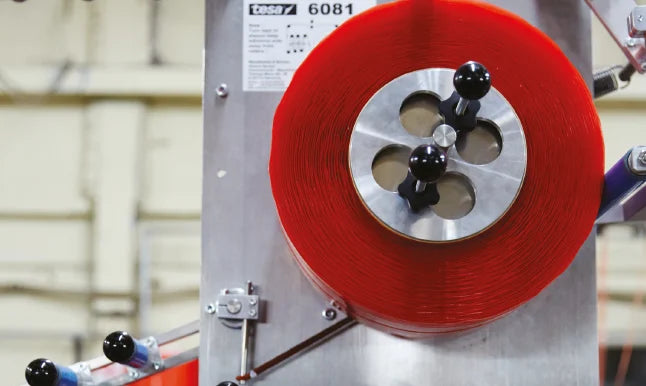

Sometimes standard strength just doesn’t cut it. If superior holding force is what you are after we’ve got you covered. We can extrude high-strength anisotropic ferrite and neodymium profiles to match your requirements.

We manufacture an extensive range of bespoke profiles for:

• Automated Guided Vehicle Sensors

• Indoor and Outdoor Advertising

• POP and Inventory Control Shelf Displays and Dividers

• General Signage

• Warehouse labelling

• Engineering and OEM applications

• Point-of-purchase (POP) shelf displays and dividers

• Profiles ready to be inserted into plastic and aluminium profiles, held captive without the need for adhesive